Plasma height control – Powermax air plasma systems

Powermax air plasma systems used with a Sensor PHC offer metal fabricators an entry-level mechanized plasma cutting solution with excellent cut quality and consumable life. The tightly coupled designs of the Powermax and Sensor PHC for Powermax air plasma systems make installation and operation easy. Reliable, voltage-sensing torch height controls improve plasma system performance by automatically positioning the torch at the correct heights for cutting and piercing for better cut quality and improved consumable life. The Sensor PHC with Powermax air plasma systems utilizes advanced microprocessor technology and arc voltage closed loop feedback to automatically maintain desired torch height during cutting to provide greater accuracy, repeatability and cut quality. Height controls without programmable pierce and cut height.

Pierces on 6 mm (1/4″) mild steel

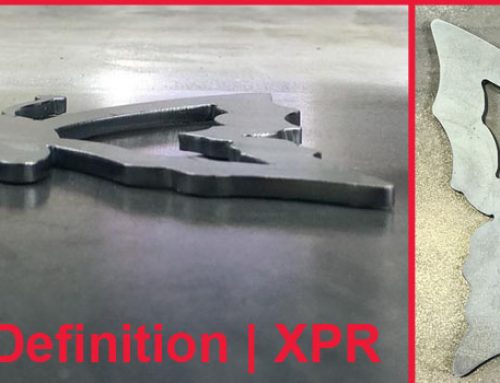

Sensor PHC No Sensor PHC

1st cut sample, maximum kerf angle 3° 4°

451st cut sample, maximum kerf angle 4° 11°

Better consumable life

Spatter during piercing prematurely damages the nozzle

presents a threat to the nozzle and shield. Setting the torch

higher during piercing avoides spatter damage, prolonging

consumable life.

The Sensor PHC offers programmable settings for both pierce

and cut heights to automatically position the torch.

Improved cut quality performance

Maintaining the torch at heights recommended in Hypertherm

cut charts improves cut quality by positioning the plasma

arc for the straightest cut. The Sensor PHC offers improved

quality over the entire life of the consumables by automatically

controlling torch height while cutting.

The following cut-edge angle dimensions were measured

at the beginning and end of a 450 pierce-and-cut test for

both setups.

Angles were measured on all four sides, all four samples. The lower the number, the

better the cut quality. The angles will vary with thickness.