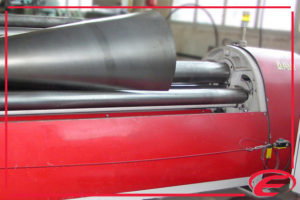

MCA - FOUR ROLL

DAVI 4 ROLL PLATE ROLL

DAVI MCA – FOUR ROLL PLATE ROLL

Born in Italy in 1966, DAVI is the world’s largest manufacturer of plate rolls, angle rolls, high productivity lines and customized rolling machines in terms of sales volume, employees, production, assets, rating.

DAVI with Engineering machinery have delivered dozens of machines for special bending applications in local markets and we have more than 11,000 components available at the factory logistic center. DAVI combined with our local knowledge offering a full customer support package following the customer from installation and training to remote support provided by the most experienced service engineers in the industry.

We offer DAVI plate rolls in three- and four-roll plate rolls designed for heavy-duty applications, including its MCA automatic line. This comes equipped with the company’s self-programming CNC system, which integrates with automation systems to reduce the need for additional labor.

DAVI 4 ROLL FEEDING:

ACCURATE FEEDING

Both clamping rolls are powered, with two independent hydraulic motors, and they are braked hydraulically, safely, instead of using low efficiency, consumable brake linings common to other brands.

HORIZONTAL FEEDING

Plates are loaded horizontally to allow the use of an in-feed conveyor and automated loading and unloading systems. The machine, CNC controlled, becomes an automated un-manned rolling center, with a cycle time extremely short, ideal for high quantity productions.

DAVI 4 ROLL PLATE ROLL EXCLUSIVE BENEFITS

- SERVO-TRONIC

Servo-Tronic is more accurate than any previous hydraulic, electronic or mechanic (torsion bar) parallel system, and keeps the machine’s side rolls parallel, even in case of electronic problems (less down-time), as it has a dual, independent but integrated, parallel control system (Davi Patent).

- PLANETARY PREBENDING

It allows for excellent roundness, thanks to the Planetary movement of the side rolls (Davi patent), moving them to the center of the machine (the tightest geometry available), compared to the inclined linear guides of other brands that, especially on large diameters, move farther away from the central roll and the plate clamping.

- DAVI TECHNOLOGY

Planetary Guides (friction-free, mill-scale-proof, Lubrication-less, Maintenance-free), Permanent Lubrication, Energy Saving, digital Roll by Wire and the dual Servo-Tronic parallel system (most Davi Patented), make it innovative, state-of-the-art, easy to be operated, highly productive, very accurate, reliable and maintenance-free.

- DAVI AUTOMATION

DAVI is the only manufacturer with an inside R&D, a team of experts, that engineer and realize the automation and the CNC that manage all its rolls.

- DAVI R&D

DAVI R&D has developed a new engineering and manufacturing philosophy, removing completely all the previous several electrical connections starting from the electric cabinet and going though the entire machine.

- DAVI CNCs

DAVI CNCs are user-friendly and “self-programming” (the most important help to the operator, even without experience), available to any customer, according with its range of activity and application.

Interested in finding out more about our Towermak Machine? - Get In Touch

ONE PHASE CYCLE

Unlike on a three roll plate rolling machine, there is no need to pre-bend the two edges of the plate first and then roll the cylinder. A cylinder can be rolled, including the pre-bending of both ends, feeding the plate forward through the rolls in a single motion.

Innovative and exclusive in design, to roll plate up to 10-15 mm (1/2 inch) thick. Accurate, fast, easy and intuitive, it is the most high-tech plate roll for “light gauge” in the market.

CNC CONTROLLED

Different choices of CNC controls are available, from an entry-level, user-friendly CNC to roll parts in automatic mode or more powerful and advanced DAVI CNC controls in the industry which can be self-programmable reducing the need of the most experienced plate roll operator.

ACCURATE FEEDING

Unlike other brands using brake linings that wear out, Davi incorporates the safety of automatic and hydraulic assisted braking for both clamping rolls to ensure accurate plate feeding.

HORIZONTAL FEEDING

Plates are loaded horizontally to allow the use of an in-feed conveyor and automated loading and unloading systems. The CNC controlled plate roll then becomes an automated un-manned rolling center greatly reducing cycle times, ideal for high quantity production runs.

SERVO-TRONIC

The patented, state-of-the-art Servo-Tronic synchronized roll parallel control uses hydraulic and electronic systems simultaneously for the most accurate parallel system on the market over other brands using just hydraulic, mechanical (torsion bar) or electronic systems.

PLANETARY PREBENDING

The Davi patented Planetary Swing Guide technology wraps the side rolls towards the center of the machine’s top roll to allow the tightest geometry available in the market compared to the inclined linear guides of other brands that, especially on large diameters, move farther away from the central roll and the plate clamping.

DAVI TECHNOLOGY

Davi uses only the most state-of-the-art technology, integrating digital Roll by Wire, permanent lubrication and dual Servo-tronic parallel system allowing for ease of operation to produce quality parts accurately and reliably and ensuring the most maintenance-free plate roll on the market today.

ISO – MADE IN ITALY

Davi is proud to say that all of the plate rolls produced are “”100% Made in Italy””, producing machines that comply with the tight ISO 9001:2008 certification standards which are a MUST in today’s competitive production environments. Like it’s Italian high-tech neighbors such as Ferrari, Maserati, Lamborghini and Ducati etc., Davi benefits from the engineering “”passion”” of it’s local area to build plate rolls with the most technological advancements in the market.

The worlds number 1 plate rolls can make your production / faster / more accurate and most importantly more profitable with consistent cone or cylinder rolling on various material metals.

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.