Swift-Jet Powerful Water Cutting

Water Cutting Solution

Swift-Jet Powerful Water Cutting

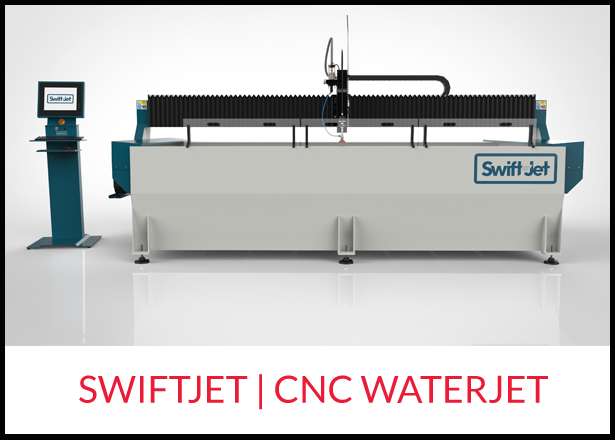

Thanks to Swift-Cut, it’s never been more affordable or achievable to own a water-jet cutting system. Waterjet technology produces excellent fine-feature cut quality with low edge taper, no heat-affected zone, a narrow kerf, and dross-free cutting. It also offers the ability to process nearly any material and a thickness range capability unmatched by other cutting technologies. The Swift-Jet machine with its easy to use software and powered by Hypertherm HyPrecision pumps provides high sector leading cutting on a wide range of materials at a low-cost investment. Easy to use with exceptional aftercare and support, the Swift-Jet is the answer to affordable, high precision, high quality in-house cutting.

Introducing Swift-Jet – our new, affordable and easy-to-use water cutting solution. Offering precision cutting, this smart machine can be used to cut textiles, rubber, foam, plastics, leather, composites, stone, tile, glass, metals, food, paper and much more. Our machines are calibrated using the very latest Renishaw software and ballbar testing equipment, ensuring outstanding accuracy. This product provides supreme value with high quality design, build, componentry, pump, software and installation and post-sale technical support and training.

Our system package has been assembled to offer a complete solution to fulfill your cutting needs. With the rise of a variety of industries seeking in-house capabilities to design, develop and create their own projects and wanting to avoid expensive outsourcing, owning a Water-jet Profiling System is becoming an essential part of their business.

Swift-Jet Water Cutting Machine offers:

Waterjet Applications | Materials

The Swift-Jet CNC Waterjet Profiling System can cut almost any material. In pure waterjet mode, it can quickly and accurately cut soft materials such as rubber, foam and other gasket material. In the abrasive waterjet mode, it can cut almost any other material over a very wide range of thicknesses.

- Unbelievable cut quality.

Creates in-house research and development opportunities.

Provides you with the ability to prototype components and guarantee quality.

Eliminates timescales waiting for outsourced parts.

Reduces cost and removes reliance on outsourced profiling.

Increase in turnover and the opportunity to diversify.

Some Features of the SwiftJet Water Cutting Machine

- SOFTWARE

Omron industrial CNC control system provides a robust and dynamic controller with online diagnostic functionality

- OPERATORS CONSOLE

Ergonomic standalone operators console with touch, keyboard and mouse inputs.

- WATER TANK

Epoxy coated heavy duty steel water tank is long lasting and delivers stability for precise cutting.

- CUT QUALITY

5 cut quality modes from fine to rough.

- SHEET ALIGNMENT

Align the cutting path with misaligned sheets on the cutting bed.

- BENEFITS

– No heat ingress into material – Precise repeatable cuts – Can cut a range of materials including metals, stone, plastics, wood and foam – Weld ready parts

Interested in finding out more about our Plasma Machines? - Get In Touch

Our latest Hypertherm | SwiftJet Install

CNC Waterjet cutting offering precision cutting, this smart machine can be used to cut textiles, rubber,

foam, plastics, leather, composites, stone, tile, glass, metals, food, paper and much

more.In fact, cut quality is so good the customer is considering there second system.

Water jet cutting is a non-thermal cutting method using only natural sand and water to cut almost any material. The brittle cutting process give a smooth cutting surface with no slag or heat affected zones, and there is less need for post processing. All materials can be cut by the same water jet machine, from soft rubber and plastics to the hardest metals and ceramics. A CNC operated water jet cutter ensures identical parts independent of volumes and with a minimum of waste material.

Swift-Jet is our new, affordable and easy-to-use waterjet profiling solution. Offering precision cutting and superior build quality, this smart machine can be used to cut textiles, rubber, foam, plastics, leather, composites, stone, tile, metals and much more. Our machines are calibrated using the very latest Renishaw ball bar testing equipment, ensuring outstanding dynamic positioning and repeat-ability.

Waterjet can certainly replace plasma, laser, milling, routers, and EDM for many applications, but more importantly, most workshops find that waterjet complements these other technology investments thus improving overall shop efficiency.

Waterjets typically vary only cut speed going from one material to the next and cutting forces are very low, resulting in very short art-to-part. This attribute is very unusual in manufacturing. The equipment is extremely quick to setup without the need to change cutting parameters such as water pressure, abrasive type, abrasive flow rate, and orifice size when going from one material to the next.

Waterjet systems like the ones from Engineering Machinery are available with different levels of precision capability. A machine tool equipped with a basic waterjet cutting head, sometimes called a conventional waterjet head, can cut a +/- 0.254 to 0.381 mm accurate part out of any material up to approximately 3” (76.2 mm) thick. Beyond that the finished part is less precise. It is possible to cut a part to tighter tolerances with a conventional waterjet, but to cut to +/- 0.127 mm tolerance the machine cut speed must be reduced to approximately 10 to 15% of maximum cut speed.

Improving material utilization adds cash directly to the bottom line. Fabrication/engineering workshops usually cut from large plates and machine shops normally cut from bar stock or smaller work pieces.

The manufacturing community at large has a basic knowledge of waterjet – the fact that it’s a cold cutting process and can cut almost anything. When faced with a tough manufacturing problem, they often seek out shops with waterjets to give the technology a try.

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

Cut your intricate digital designs faster and more accurately than any other metalworking power tool. Create projects with some of the world’s strongest and most durable materials. From automotive parts, to real structural components, to weatherproof art and signage.

From pc design to a cut part in minutes – that is why our customers purchase the low cost cnc plasma table.

Our affordable CNC Plasma Cutting Systems are built in the UK and will be a great addition to your business / hobby shop. School – college or small business.

An exclusively industrial fabrication process is now small and affordable enough to operate in your house / school or garage . Roll the machine into your work area and store away when it is not being used.

Safety covers

Covers offer protection to key components against sparks and molten material.

Improving material utilization adds cash directly to the bottom line. Fabrication/engineering workshops usually cut from large plates and machine shops normally cut from bar stock or smaller work pieces.

The manufacturing community at large has a basic knowledge of waterjet – the fact that it’s a cold cutting process and can cut almost anything. When faced with a tough manufacturing problem, they often seek out shops with waterjets to give the technology a try.