Waterjet Pumps

Hypertherm Waterjet Pumps

Hypertherm Waterjet Pumps

In addition to producing exceptional fine-feature cut quality, waterjet technology can handle a wider variety of materials and thicknesses than any other cutting method. Whatever your waterjet application – from small prototype jobs to 24/7 manufacturing – there’s a HyPrecision™ cutting machine to meet your needs.

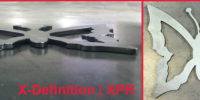

Waterjet technology produces excellent fine-feature cut quality with low edge angularity, no heat-affected zone, a narrow kerf, and virtually dross-free cutting. It also offers the ability to process a variety of materials and a thickness range capability unmatched by other cutting technologies.

Incorporating proprietary Advanced Intensifier Technology (AIT), Hypertherm HyPrecision™ Waterjet Pumps are the hardest-working, most cost-effective waterjet pumps in the world. The Basic Series 15, 30, and 50 products are engineered to deliver long-life reliability and uncompromised safety for the lowest cost of ownership.

HyPrecision Predictive waterjet pumps:

The new HyPrecision™ Predictive pumps incorporate patented Seal Maintenance Technology™ and service-friendly capabilities that substantially reduce maintenance costs and disruption caused by non-planned service.

With standard features such as our proven Advanced Intensifier Technology™ and closed loop proportional pressure control, these latest generation waterjet systems offer you even more consistent cut quality while ensuring improved reliability and easy, straightforward service.

Do not end up with too little or too much when it comes to your waterjet. Get the right waterjet for your application by talking to your Hypertherm experts.

Key features of the Waterjet Pumps

- EASIER SERVICING

Hydraulic rod seals and plunger bearings are readily accessed from the outside of the hydraulic end cap.

- LONGER LASTING

Hydraulic center section features an advanced piston design, which minimizes seal wear and improves component life.

- STREAMLINED ACCESS

Check valve utilizes a screwless, low-pressure poppet design that enables quick evaluation of key contact surfaces. This feature also allows for noticeably faster component replacement.

- OPTIMIZED SHIFTING

Advanced electronics provide smooth, reliable shifting for optimum cut quality. Shift times are even monitored to ensure optimal pump performance.

- SIMPLER HIGH PRESSURE ENDS

Durable, threaded-rod design simplifies high-pressure end removal for quick seal maintenance. Meanwhile, the nonthreaded cylinder design increases reliability.

- PROLONGED SEAL LIFE

Large diameter ceramic plunger produces more water per stroke with reduced friction, yielding maximum seal life.

Interested in finding out more about our Plasma Machines? - Get In Touch

Hypertherm Waterjet Pumps

Hypertherm – Legendary Support. Committed to Innovation.

An unstoppable force in Waterjet.

Advantages of waterjet Waterjet technology produces excellent cut quality with low edge angularity, no heat-affected zone at all, a narrow kerf and virtually dross-free cutting. With a narrow kerf, waterjet technology produces excellent fine feature cut capability.

Typical applications include:

Shape cutting of ¼” and thicker aluminum

Net size cutting of ½” and thicker stainless steel

Blank cutting parts for final machining

Short run lots of sheet metal parts

Screen cutting

Converting plate stock to bars

Precision cuts in ½” and thicker mild steel

Hardened materials

Intricate shapes in delicate materials

Custom shims in stainless steel and exotic materials

Tube cutting

When you factor in the cost to purchase, own, and operate, you’ll discover that Hypertherm HyPrecision waterjets outperform all other systems, typically by 20% or more. Those savings go straight to your bottom line.

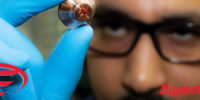

Advanced Intensifier Technology (AIT)

At the heart of every HyPrecision waterjet, you’ll find our Advanced Intensifier Technology (AIT). By rethinking the way the intensifier pump works, we were able to make it work harder, last longer, and require less service time.

Result: the most reliable, most cost-effective waterjet in the world, and a pump that:

- Delivers optimum cut quality

- Is easier to service

- Lasts longer

- Is easier to access

- Requires less routine maintenance

Industries and markets include:

- Agriculture

- Military and defense

- Medical

- Energy

- Architecture

- Aerospace

- Colleges- Schools

- Fabrication Workshops

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.