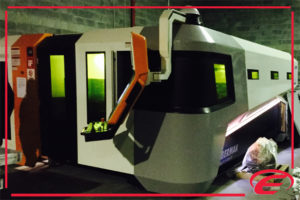

Fibermak G-Force Laser Cutting Machine

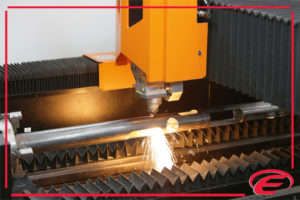

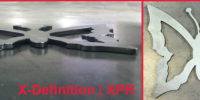

FIBER LASER CUTTING TECHNOLOGY

CNC Laser G-FORCE

Fibermak G-Force is designed with the servo motor concept, A machine equipped with a servo motor may reach up to 4G acceleration with its rigid bridge as a result of dynamic analyses performed and its perfect design. Thanks to the high acceleration that provide great advantages while switching between parts, production time is decreased and efficiency is increased by 15% per hour in average. The more complex the part to be processed, the greater the productivity.

Produced by using long-life and high quality components together with its strong body structure, Fibermak G-Force is designed to operate continuously and precisely even under the most severe conditions.

G-FORCE CONSISTS OF SEVERAL SECTIONS:

LASER SOURCE: The beams produced in the modules of the laser source are transported to the cutting head by means of the fiber cable without any loss.

COOLING (CHILLER) UNIT: The part that provides cooling of the laser unit, the collimation part on the cutting head, the laser modules and the linear motors, it has a water-based cooling system.

SUCTION UNIT: It provides a healthy working environment by absorbing the fumes and small particles formed during cutting. Runs automatically when cutting is started.

CONVEYOR: Is a band system that carries the parts and slags falling from the grids to the collection chamber after the cutting process in the system.

Key Benefits of the CNC Laser G-Force

- MACHINE UPDATE

Because the machine hardware and software are designed and implemented with a very advanced vision by the ERMAKSAN engineers it may work with up-to-date performance for many years.

- ULTRA FAST COMMUNICATION

Through the Ethercat communication protocol, all machine equipment are controlled at ultra-speed. The total time between placing of an instruction and its execution is at microsecond level.

- CUTTING AT MINIMUM TIME

In CNC controlled machines such as Fibermak, the flow of G codes is important in the performance duration of a process. In Fibermak, the G code flow is designed to achieve the desired result from the shortest path.

- BACK-UP

It is possible to restart the machine within minutes by means of a system backup against possible errors.

- SMART FACTORY SOLUTIONS

It allows businesses to build intelligent factories with a rapid and flexible structure, that provide innovation by improving processes, and that improve productivity and minimize errors by increasing efficiency with industry 4.0 solutions.

- CREATING A WORK LIST

By creating a work list, dozens of programs may be queued and run automatically at a single time. Also any function programmed with the easy operating buttons on the lower part of the control panel may be operated with a single key.

Interested in finding out more about our G-Force Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.