Pivot Band Saws

Manual Band Saw Metal Cutting

Pivot Manual Band Saws

Our range of metal bandsaws were the industry’s first to incorporate swing-head capability – an innovation that has taken the industry to a different level.

These are versatile, miter-cutting, scissors style machines designed for multiple medium duty applications at oil refineries and machine shops, heavy fabrication workshops, trailer manufacturers, automotive shops, and agricultural applications to name but a few. Our range of Bandsaw models are available in manual, semi-automatic, and fully-automatic models, with the mitering capability up to 60º.

Our pivot bandsaws from MEP & Cuteral developed by in-house engineers to produce a diverse range of horizontal metal bandsaw machines to meet our customers demands for production.

Each different range of machines is with excellent design that combines the control system and high transmission efficiency, which offers products with more stable quality to you the customer.

Pivot Manual Band Saw Cutting:

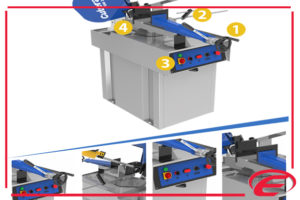

SHARK 281 CCS (Cut Control System) manual bandsawing machine to cut from 0° up to 60° left. Other than the manual cut mode, the sawing machine can make single cuts without operator, using the head weight controlled by a hydraulic brake: after the cut the band stops. The frame at this point is manually lifted to the position needed in order to reposition the bar to cut.

In the version with pneumatic vice (MA) the vice is opened/closed by a manually-controlled valve (optional with pedal control).

A FEW FEATURES: See Below.

Some Key Features of the Pivot Manual Band Saws

- VICE

– Vice with fast clamping device.

- PUMP

– Electric pump for band lubrication and cooling

- BAND CLEANING

– Wire chip brush for band cleaning.

- CUT CONTROL

– The CUT CONTROL SYSTEM (CCS) can be retrofitted on machines out in the field.

- WORKING SURFURE

– Wide working surface with rotating table installed on a roller bearing, dia. 265 mm, preloaded with thrust bearing

- MANUALS

– Service keys and instructions manual for maintenance and spare parts list.

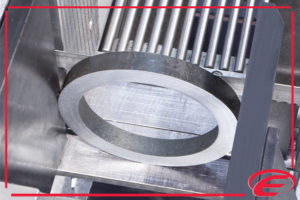

One of the key advantages our customers tell us with a bandsaw is the reduction in material wastage. Mep and Cuteral Bandsaws have a smaller kerf than other tools, which results in reducing wastage. Other tools have wider blades, where bandsaws feature narrow blades.

Our pivot bandsaws unlike other cutting tools, this tool is not restricted to cutting a specific type of material.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.