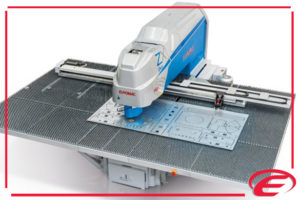

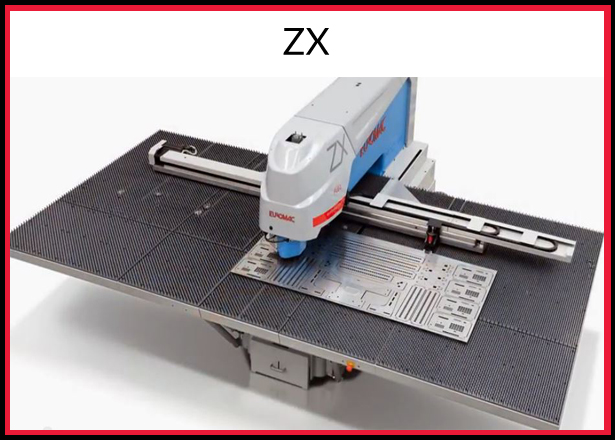

ZX Plus Flex Punch Press

Sheetmetal Punching

ZX Plus Flex Punch Press Machine

EUROMAC is one of the largest builders of punching equipment in the world. The machines are manufactured in Italy and distributed throughout Northern Ireland and the Republic of Ireland. Euromac manufacture CNC Punching Machines, Notchers, and Hydraulic Horizontal Benders.

Precision and stability. Your best guarantees Designed by FEM (Finite Element Method), it provides resistance of 700N/mm² with an increase in size that enables the machine to operate at higher speeds with greater stability and thus machining precision. The head is directly built into the monoblock. Thanks to the more stable frame, machining

and handling speeds can be increased even on large, heavy sheet sizes, also assisted by the third clamp and the balls fitted on the worktable. In other words, Euromac punching machines meet the demand for high-performance, high-output units while also cutting operating costs.

Much more than just a punching machine: a complete Sheet Metal Working Centre

Often, we don’t make full use of all the possibilities technology has to offer. Euromac punching machines are really complete sheet metal working centres. Every station can be tooled for forming, bending, beading and threading.

C- Frame monoblock:

The new frame with an increase of dimensions enables the machine to operate with higher speeds thus ensuring greater stability and working precision.

Our machine frame is a normalized nodular cast iron monoblock in Meehanite® with 700N/mm2, designed with FEM (Finite Element Method), punching head directly built into the monoblock frame.

In practical terms this means a more robust (no welding points), precise and reliable structure being at the same time compact, hence using less floor space and allowing flexibility in loading different sheet sizes.

Key features of the ZX Plus Flex Punch Press Machine

- TOOLING FLEXIBILITY

Choose the setup you need: from Single tool (A, B, C or D up to Ø 88,90 mm) to Multitool. Why talk about number of “stations”? What you need is the flexibility to easily and quickly setup your machine with the proper tools needed for your job. Euromac gives you this flexibility, we talk about number of “tools”.

- AUTOINDEX SYSTEM

The unique direct drive tool rotation in the Euromac autoIndex stations reduces mechanical components and adds strength, resulting in increased reliability and reduced maintenance. This improves productivity while reducing cost (patented).

- VACUUM SYSTEM

Our vacuum system prevents scraps from remaining on the sheet, potentially damaging its surface and sometimes even the tool itself. Strongly recommended when processing thin materials, material with protective film or aluminium in general. Optional on all models.

- LOADING & UNLOADING

Easy loading of material for machining and unloading of finished parts generates much higher productivity for you.

- MACHINE CAPABILITY

As for all Euromac products, flexibility is key: just one machine can process a vast assortment of sizes. All sizes between the stated minimum and maximum dimensions can be processed.

- CONSOLE

The Euromac console is equipped with a UPS for electrical backup avoiding data loss in case of a power failure. TopPunch® is also able to recover an interrupted program and restart operation from any point.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Computer numerically controlled (CNC) punching is a sheet metal manufacturing process that is carried out by CNC punch presses. These machines can be either a single head and tool rail (Euromac)design or multi-tool turret design. The CNC punching machine is programmed to move a sheet of metal in an x and y direction so as to accurately position the sheet under the machine’s punching ram ready to punch a hole or form.

CNC turret machines from Euromac can create many shapes, from simple circles or rectangles to overlapping geometrical 3D designs.

CNC punching plays a significant role in sheet metal manufacturing industries in our local markets, delivering machinery with high accuracy, speed that is competitively priced is the reason our Euromac Turret punch systems are the most popular choice for our customers.

The processing range for most CNC punch presses is 0.5mm to 6.0mm thick in a range of materials including steel, zintec, galvanised steel , stainless steel and aluminium. The choice of hole punched can be as simple as a circle or rectangle right through to special shapes to suit a specific cut out design. By using a combination of single hits and overlapping geometries, complex sheet metal component shapes can be produced. The machine may also punch 3D forms such as dimples, taptite® screw thread plunges, and electrical knockouts etc on either side of the sheet, which are often employed in sheet metal enclosure design.

By using our Euromac machinery you can have a large number of strokes, with several different tools in turn, a turret press may make a wide variety of parts without having to first make a specialised press tool for that task. This saves both time and money, allowing rapid prototyping or for low volume production to start without tooling delays.

A hydraulic ram forces the tooling into the sheet material held in position by clamps on the bed of the punch. The tooling can then be used to create a number of shapes like:

-

- Louvres

- Centre punches

- Countersinks

- Embosses

- Knockouts

- Hinge forming

Euromac machines are tailored to meet demanding market requirements; the combination of state-of-the-art technologies and unique concepts assures you advanced, productive and competitive products at all times.

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.