Digibend 800 CNC

Bending machines

Digibend 800 CNC Bending Machine

Every steel and copper workshop can take advantage of a Digibend 800 CNC

Are you using or thinking to use a conventional press brake to bend small parts, thick material or bus bars? Then you need to look at a Digibend a powerful and versatile horizontal bending machine. Bending horizontally on a flat bed has two main advantages:

– your part will always be perfect since you lay on a flat surface instead of referencing against two small fingers.

– you can bend a close loop (like a 9 shaped part), hence saving time and possibly also a welding operation.

The Digibend takes advantage of this and with its unique features goes beyond.

Digibend Tools:

Euromac offers a variety of standard tools for a Digibend and changing from one tool setup to another is fast and easy.The Digibend table is a machined out of a single monoblock of Meehanite® 700N/mm2 (no welding points), the cylinder is completely embraced in the structure and the RAM is guided in all its stroke in order to be able to maintain the highest accuracy even in the high tonnage demanding applications. The strong structure combined with the unique control system and the specifically designed hydraulics ensure the repeatability accuracy (0,05 mm) even after thousands of bends.

The flexible and strong design of the Digibend table (with antimarking treatment) together with the easy to use control system (2 axis CNC controlled) allows any

customer to create their own custom tools for special applications

With Digibend you get the maximum bending flexibility

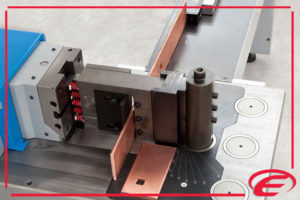

- 2 JAW BENDING TOOL WITH SET OF FLANGES

2 jaw bending tool with set of flanges for flat and shaped bars up to 90°. Max 60 x 20 mm.

- 2 JAW BENDING TOOL

2 jaw bending tool for thick wall pipes from 3/8″ gas (17.2 mm) up to 2″ gas (60.3 mm) and round bars, up to 90°.

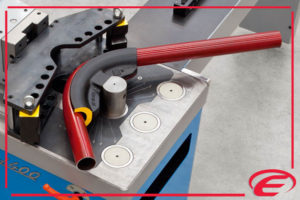

- ROTARY BENDING TOOL

Rotary bending tool for pipes, round and box tube, up to 180°. max Ø 50 mm.

- REVOLVING PIN DIE

Tool single V die with revolving pin (mark-free bending) for thick plates. Max 200 x 30 mm.

- PIN BENDING PUNCH Ø 80 mm

Pin bending punch Ø 80 mm with antiflexion bar for bending a closed loop into thick wall bars. Max 200 x 15 mm.

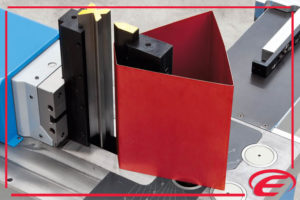

- PUNCH AND DIE H=400

Punch and die H=400 mm for bending plate sheets. Max. 400 x 4 mm.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.