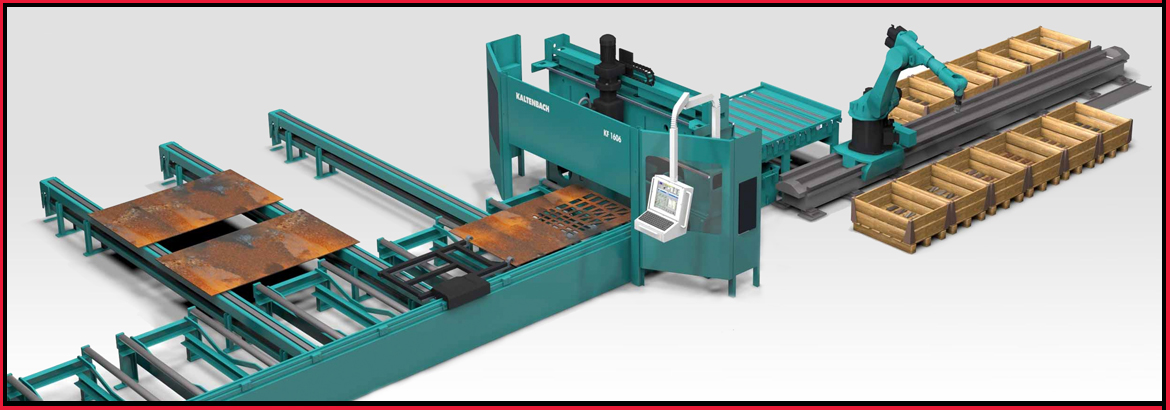

PLATE CUTTING AND DRILLING CENTRE

The KALTENBACH product range starts with the company’s core, circular and band sawing machines and extends to a comprehensive portfolio of Plate Cutting & Drilling, profile drilling machines, profile processing robots, welding robots, plate processing centres, punching/shearing systems, shotblast lines, preservation systems, marking equipment and the accompanying measurement and material transport systems.

The product range is designed for the efficient and reliable processing of steel, aluminium and other non-ferrous metals- Processing angle iron, flat stock and channel in a one pass process; makes the anglemaster series we offer from Kaltenbach the answer for progressive fabricators. The technologies of punching, shearing and marking incorporated into one space saving design yields high levels of productivity and accuracy for your toughest applications

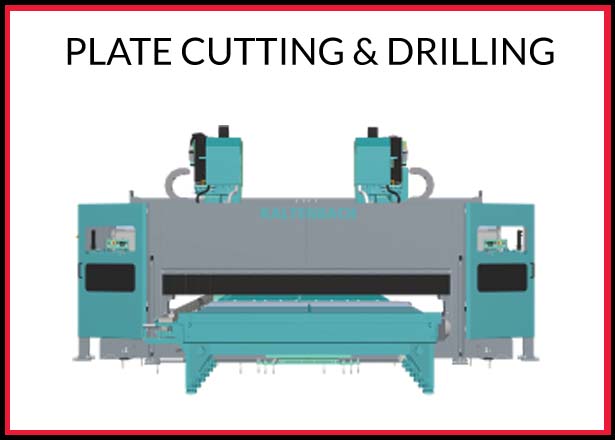

Plate Cutting & Centre Drilling

BENEFITS AT A GLANCE

- Diverse manufacturing technologies such as drilling, milling, countersinking, thread-cutting, contourmarking, oxyfuel and plasma cutting bundled on a single machine

- Powerful drives for optimum performance and low production times

- Higher spindle speeds ideal for milling

- 14-place tool changer for faster setup times

- Less space needed for measuring carriage

- Measuring carriage at the side runs through the machine to optimise plate fixation throughout the entire machining process

- Two processing units for parallel machining and higher efficiency

- Durable construction provides the basis for a long-term investment

- Fully automatic handling of small parts

- Rotating swarf brush for automatic clearing of chips in front of cutting processes

- Optionally with downholder roll for optimum contact pressure of the plate when milling larger contours

- Higher spindle speed for drilling and milling

Profile Drilling Machines

BENEFITS AT A GLANCE

- Robust, low-vibration design prolongs machine and tool life

- Machine portal in robust welded construction incorporating two horizontal and one vertical drilling unit

- Three drill axes with a total of 18 tools and automatic tool-changing system with 6 tools per tool changer

- Efficient drilling, contour-marking, centre-marking, counter-sinking and thread-cutting on all three drill axes simultaneously

- Powerful clamping system reliably holds material and reduces vibrations to prolong band life

- Intelligent material measurement integrated into clamping system for greater process reliability

- Rapid/working feed concept for shorter idle times

- Servomotor and ball screw for high-precision drill axis positioning and feed control

- A saw can be incorporated to create a saw-drill combination

- Powerful drives and modern spindle construction for high- performance machining

- Milling of standard contours

- Carbide and solid carbide drills can be used to significantly reduce production times

- Servo motors with a rotation up to 2.500 rpm

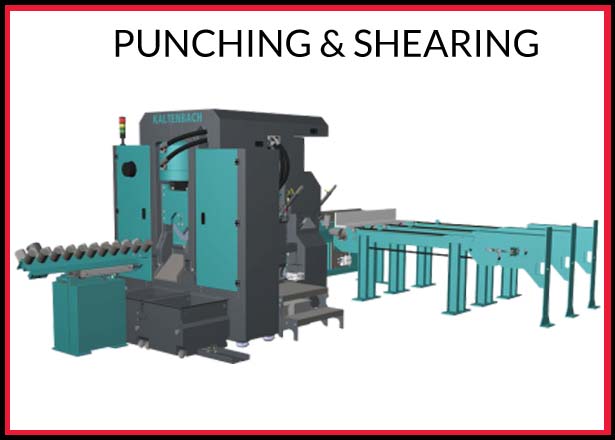

Punching & Shearing Systems

BENEFITS AT A GLANCE

- High punching and shearing force

- Robust, low-maintenance design for long-term investment

- Automatic die clearance setting for optimum shearing results

- Quick-change tooling system to minimise idle times

- Material transportation speed of 100 m/min for low transportation times

- Sorting system for good parts

- Triple marking unit marks up to 3 characters a second

- The design is influenced by years of experience in punching and shearing

- Sturdy construction for low vibration and thus improved punching and shearing results

- Compact machine design for space-saving installation

- Fast service support through help desk via remote support

Interested in finding out more about our Pressbrake Machines? - Get In Touch

PLATE CUTTING AND DRILLING CENTRE

The KALTENBACH product range starts with the company’s core, circular and band sawing machines and extends to a comprehensive portfolio of profile drilling machines, profile processing robots, welding robots, plate processing centres, punching/shearing systems, shotblast lines, preservation systems, marking equipment and the accompanying measurement and material transport systems.

The product range is designed for the efficient and reliable processing of steel, aluminium and other non-ferrous metals- Processing angle iron, flat stock and channel in a one pass process; makes the anglemaster series we offer from Kaltenbach the answer for progressive fabricators. The technologies of punching, shearing and marking incorporated into one space saving design yields high levels of productivity and accuracy for your toughest applications

If you have any product-related queries then contact us, & For new updates follow us on our Facebook page.