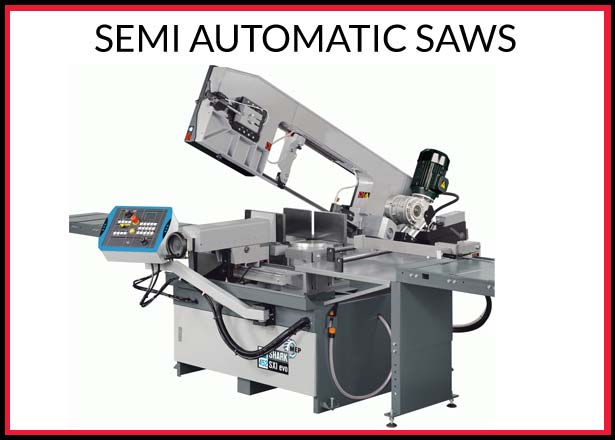

Semi Automatic Bandsaws Range

Industrial Metalworking Band Saws

Semi Automatic Metal Working Band Saws

Semi automatic horizontal bandsaws provide quick and efficient, single cutting of all varieties of material such as stainless steels, super alloy and mild steel, whether in tube, structural section and solid or non ferrous materials, solid plastic, aluminium profiles, and other variants.

Semi-automatic horizontal bandsaws provide quick and efficient, single cutting of all varieties of material. The range of heavy duty, semi-automatic bandsaws supplied by Engineering Machinery and services covers all types of configuration, built by leading manufacturers such as MEP ( Italy ) & Cuteral ( Turkey ). Benefits of using a semi-automatic bandsaw are to be able to steplessly vary blade speed, maintain blade tension by hydraulics, bundle clamp materials, powered swarf conveyor, swarf extractors and more.

With such an extensive range Engineering Machinery Northern Ireland can supply the best fit machine to suit your budget and applications whatever the industry may be.

A FEW FEATURES OF THE SEMI AUTOMATIC BAND SAWS:

– Console with all centralized controls, installed on an articulated arm to follow the operator in every operating position for the controls and the EMERGENCY.

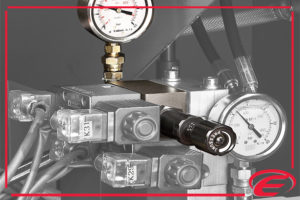

– Latest generation hydraulic control unit, with high efficiency and low energy consumption.

– The headstroke, according to the dimensions of the material which has to be cut, is set directly from the control panel.

– Low voltage soft keyboard, in polyester, with thermo-shaped buttons, with tactile feeling and sound signal when operating.

– Display for the following messages: + diagnostic + alarms (cause description) + input and output status + cut counting + time spent for the cut made + blade motor absorption + blade tension + blade speed + numeric displaying of the head position.

Some other features of the Semi Automatic Band Saws include:

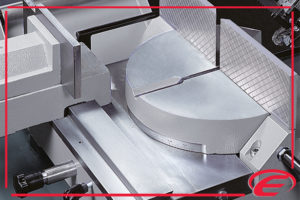

- ROTATING TABLE

– Rotating table, with etched accuracy graduation, tilting on a roller bearing with 280-mm diameter.

- SAFETY AND STABILITY

– Wide supporting surface for the max. safety and stability while cutting.

- BAR SUPPORT

– The bar support with roller, on the left of the cutting table, slides on linear guide with ball recirculation, so that it can be easily moved to cut up to the max. angles without any disassembly.

- HYDRAULIC VICE

– Hydraulic vice with fast sliding approach, movable on linear guides with ball recirculation.

- BLADE TENSIONING

– Manually-operated blade tensioning through electronic transducer.

- PUMP

– Electric pump for the band lubrication and cooling

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Features and options include steplessly variable blade speed, hydraulic blade tension, hydraulic bundle clamps, vice pressure reduction, mist spray lubrication, powered swarf conveyor and swarf extractors.

The bow descent can be controlled by speed and pressure resulting in fast cutting where there is minimal resistance, yet will automatically reduce when the load increases.

This results in fast, safe and controlled cutting, increasing production times and extending blade life. The vice is hydraulically operated and the bow hydraulically returns to just above the material. The quick mitring head allows for quick and simple angle cutting with the material positioned on fixed roller track.

Powered Vice

A semi auto band saw is equipped with a powered vice and powered bow lift cylinder. The cutting cycle is initiated by pushing a single button that closes the material clamp, starts the blade and allows the bow to descend at a controlled downfeed rate. At the bottom of the cut, the blade stops and the bow rises to a position immediately above the material. The vice clamp then opens.

Straight and Mitre Cutting

The straight cutting of billets is best suited to some heavy build machines with swivelling vice jaws, other machines have a swinging bow for easy mitre cutting.

Twin Column

A large capacity, twin column band saw has a rigid design for high performance with reduced vibration and produces best surface finish and good blade life. A pivot action semi auto saw is flexible, compact and adaptable for all applications

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.