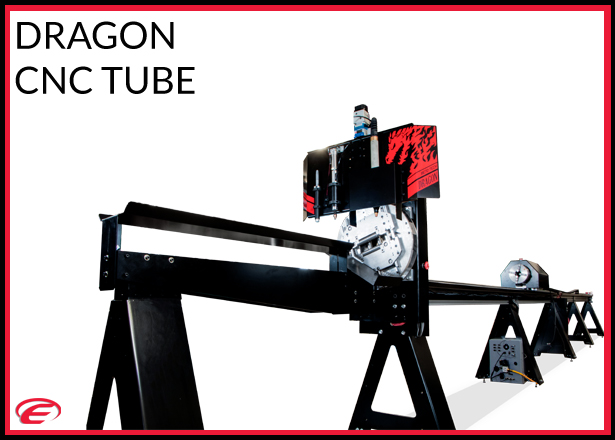

Light Industrial CNC Tube Plasma

The Dragon A400 series

Light Industrial CNC Tube Plasma

Combined with the world’s most powerful CAD/CAM software, Dragon A400 will get the job done with accuracy and speed. Our software systems are undeniably the most user-friendly CNC Plasma software on the market. Very quick and easy to learn and use, even for users that admit they are not computer-savvy.

The Dragon is capable of taking a full length of tubing, cutting it to length, notching the end profile, making holes or slots as needed, and then marking any bend locations with rotation and degrees. Bend-Tech Dragon obtains all of the necessary information from Bend-Tech Industrial software automatically. Just add your plasma machine and computer!

Included with the Bend-Tech Dragon is two powerful software packages; Bend-Tech Industrial and Bend-Tech Dragon Software. Working side by side, these products will allow you to create 3D CAD designs from scratch or convert from SOLIDWORKS, AutoCAD, Inventor, PRO Engineer, etc. into a readable format for the machine. Dragon Software will automatically create your cutting, marking and etching paths directly from Bend-Tech Industrial and comes with a nesting ability to allow several parts on the same stock tube.

CNC Plasma cutting – Round, Square, Rectangle, Tube profiles with anything you are able to design .

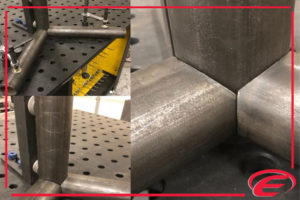

The Dragon A400 series will cut holes, notches, and other designs on round, square, and rectangular tubes with ease and accuracy

Marking Without the Guess Work:

DRAGON A400 TUBE CUTTING MACHINE

With the help of the Dragon software, the Dragon A400 series is able to engrave and mark precise bending locations & rotation values onto the tubes. These compensate for your material’s stretching and allow for flawless line-ups in your bender. It can also draw saddle marks where tubes will intersect for quick and accurate assembling.

With Bend-Tech Dragon machines, we recommend that you use Hypertherm Powermax 45 or higher with mechanized torch for the best cutting results. Bend-Tech is an official OEM of Hypertherm plasma torches, and they can be purchased through us with the Dragon machine sale.

Key Features of the CNC light industrial tube cutting dragon machine

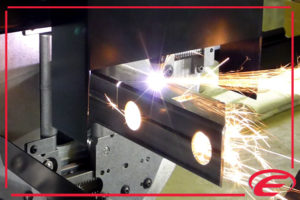

- PLASMA HOLDER & SIDE SHIELDS

The plasma holder is designed to fit most plasma cutters available on the market. We recommend the Hypertherm PowerMax series. The side shields help block sparks and debris that are emitted from the machine.

- FRONT POSITION GATE

The roller gates compress upon a center location to provide symmetrical rotation of the tube. The vise-style screw system holds itself into position. No adjustment is needed as you run a stick of raw material.

- CENTER SUPPORT LIFTER

The lifter’s motor drives it along a vertical axis to support the material and prevent bowing/whipping during operation. An air actuation system positions the roller over the rail and rotates out of the way when necessary.

- ENGRAVER

The Dragon’s improved engraver system is second to none. An inline oilier is supplied to keep it functioning efficiently. The engraver is used for part marking and for designs that are to be etched onto the material.

- LASER LIGHT

The laser light allows for material line up when using the pass through chuck capability or when needing to flip the tube end for end to reduce or eliminate the remnant drop between the chuck and the cutting head.

- MINI WATER TRAY

The mini water tray captures about 95% of the sparks. This greatly decreases the fumes experienced during plasma cutting.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Our Bendtech Dragon A400 CNC Tube and Pipe plasma is your gateway into light industrial CNC tube cutting, engraving, and marking machine. From Drawing to Finished Product faster than ever before.

Conventionally, preparing tube drawings for CNC machines would involve hours or even days of work, plus trial and error during the assembly and fabrication process – all adding unnecessary time, cost and material wastage.

Dragon software is able to take your 3D CAD drawings and then automatically unfold them into flat 2D layouts, ready for the Dragon machine to manufacture.

Work with CAD drawings designed in virtually any common format (Bend-Tech, Solidworks, AutoCAD, etc) or even hand drawings.

Dragon’s exclusive CAD to CNC software will provide fast and intelligent file handling & converting to help you manufacture the exact part you have in mind.

By reducing the ‘gap’ between your designs and the CNC machine, your work can now be done in minutes with no mistakes!

Dragon’s software’s conversion process will even compensate for your material stretching, spring-back, rotations, etc.

Includes nesting ability to allow multiple parts to but cut from the same stock tube.

The dragon is a very affordable system that will increase production whilst bringing down costs by outsourcing the same work.

- Dragon CAM/CNC Software

- Dragon Software

- Marking Station

- Center Support Lifter

- Engraver

- Laser for positioning

- Pc – controls and Console

- Hypertherm Powermax Plasma

With the help of the Dragon software, the Dragon A400 series is able to engrave / plasma cut and mark precise bending locations & rotation values onto the tubes. These compensate for your material’s stretching and allow for flawless line-ups in your bender. It can also draw saddle marks where tubes will intersect for quick and accurate assembling. Using the Tube Dragon in conjunction with a rotary tube bender you can also increase production, hold tighter tolerances, and develop new products.

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.