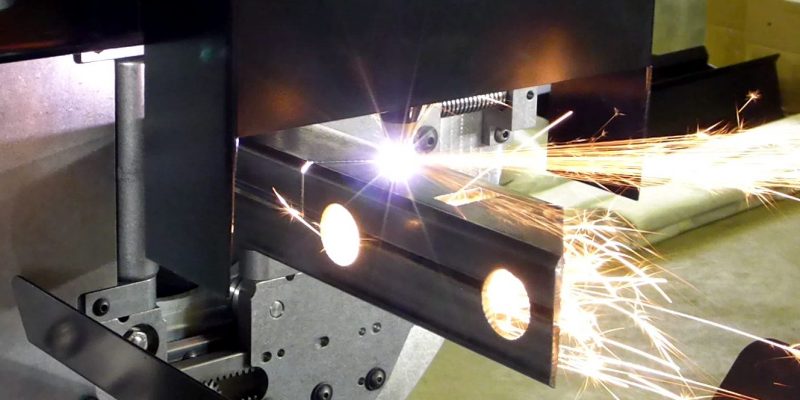

The Model 4 – System is more than a CNC Pipe & Tube Plasma Cutter.

The Dragon-series machines work in perfect harmony with our Hypertherm plasma cutting systems renowned know the island over.

The New Bend-Tech Dragon is an affordable, complete package for tube notching, cutting, and marking tubing past to 100mm in diameter. The Dragon is capable of taking a full length of tubing, cutting it to length, notching the end profile, making holes or slots as needed, and then marking any bend locations with rotation and degrees. Bend-Tech Dragon obtains all of the necessary information from Bend-Tech Industrial software automatically.

Included with the Bend-Tech Dragon is two powerful software packages; Bend-Tech Industrial and Bend-Tech Dragon Software. Working side by side, these products will allow you to create 3D CAD designs from scratch or convert from SOLIDWORKS, AutoCAD, Inventor, PRO Engineer, etc. into a readable format for the machine.

Tube Size Capacity | Hypertherm CNC Tube Plasma

The roller gate design gives the versatility of handling both round pipe and square or rectangular tube (RHS & SHS).

- Round: 13 – 152mm diameter.

- Rectangle & Square: 13 – 100mm x 13 – 100mm.

- Chuck pass through (for processing tube lengths longer than the machine): Round Pipe max 50mm,

Square Tube max 35 x 35mm. - Machine Travel Length: Max 7,400mm of travel in one position / unlimited when re-positioned.

Precision and Speed

Whether your job involves cutting out thousands of identical components or one-off rapid prototype parts,

Dragon A400 will take your workshop’s production to the next level using Hypertherm Plasma

Mark, Label or Etch with Accuracy = Assemble with ease

More than just a plasma cutter: Thanks to it’s marking capability, the Dragon A400 will bring you massive

time and cost gains when it comes to assembling your parts.

- Precisely mark and label tubes with: locations, bend order, rotations, angles, saddle marks (where tubes

will intersect for quick and accurate assembling) & much more. - Marks with permanent marker or engraver.

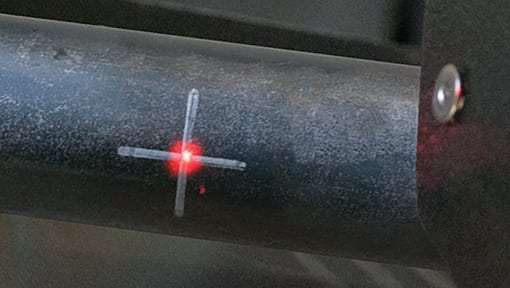

Laser Guided Positioning: Fast Indexing and Reduced Waste

Eliminate scrap, allow full utilization of tube lengths, flip the pipe (end-for-end) or work with pipe longer than

the machine? No problem!

- Dragon will create a mark or etch on the first position of the pipe.

- Release the pipe from the chuck and re-align with a Laser Pointer Light mounted to the head.

- Continue cutting, marking and etching the next position of tubing.

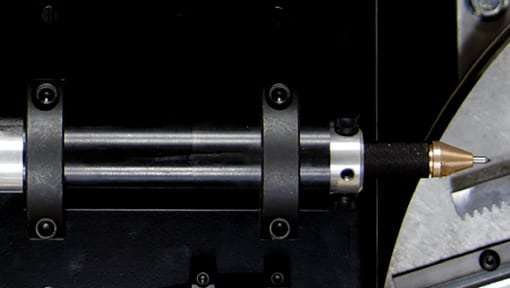

The Dragon’s engraver unit is second to none.

- Standard feature on every Dragon machine.

- An inline oiler keeps the engraver functioning efficiently.

- Used for part identification marking and for designs that are to be etched onto the material.

of up to 180kg , CNC Tube Plasma Machine -using the new Hypertherm PMX Sync.