Dual Station Ironworker Machinery

MULTI HYDRAULIC STEELWORKER

Dual Station Multi Hydraulic Steelworker Ironworker

The Kingsland Multi range of 60 up to 175 ton machines are in the Kingsland tradition of well engineered, robust steelworkers, built for a long working life. These universal machines are supplied with standard tooling including repetition support tables at punch, shear and notch stations and with easily adjusted hold-downs at all five work stations to safely control the operations. Comprehensive safety guards are fitted as standard on all work stations. Free standing on a suitable floor, they just require electrical connection to be ready for work. For two operator utilisation, the hydraulic system is activated by two shielded foot controls, one operating the

punch end cylinder, the other operating the shear end cylinder.

The shear cylinder provides the power to the three shearing and the notch stations. The system gives accurate power inching at all five work stations and allows the machine to be stopped at any position giving safe and accurate tool setting and work positioning. Limit switches at both ends of the machine control stroke length at all stations. Centralised lubrication is metered by one-shot system, being only one feature of the low maintenance requirement. An optional ‘Production Pack’ is available to enhance the machine specification, this includes: 1 low volt halogen lamp on a movable magnetic base, 1.0 m long touch and cut ruled length stop, fine adjustment facility to the punch stroke and measuring scales in the notch table.

KINGSLAND TECHNOLOGY:

Technology: linear rail and CNC controlled positioning tables

2 axis CNC-controlled positioning table:

Punching of plates, flat steel, in the web of channel and on the flange of channel and I-beams. The punching of the web in channel is effected with the flanges up and by using extended length punches. The table is delivered complete with servo-motor and 2 axis measuring system, and is equipped with an easy to operate Robosoft K210 (or optional M600) control.

Especially advantageous is the repeatability accuracy when manufacturing repeat batches and accuracy even for one-off s. The use of labour intensive manual layout is no longer required and possible operator error is eliminated. The workpiece is pushed to the CNC controlled stop, after punching the stop goes to the next position…

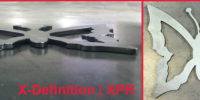

Some Key Features of the Dual Ironworker include:

- PUNCH STATION

The large punch bed area has a removable front block and is designed to give a very wide range of punching applications. A punch table with rules and guides for repetition work are fitted as standard equipment.

- ANGLE STATION

This station provides large capacity angle cutting at 90° and 45°. Angles between 45° and 90° can be achieved by first cutting at 90° and then flange trimming to the required angle in the shearing station.

- SECTION CUTTING STATION

The machines are fitted as standard with blades for cutting round and square bars. With extra equipment, the machines are able to cut, in this aperture, channel, joist, T-section and many other special profiles.

- SHEARING

The shearing unit is fitted with a simple robust holddown which is adjustable to any thickness of material within the cutting capacity of the machine. The shear feed table with adjustable guides is fitted to allow accurate feeding of materials. The guide can be adjusted to allow mitre cutting up to 45° for fl at bars or to trim the flanges of angle.

- NOTCHING

The notching station is fitted as standard with a rectangular notch table with adjustable back stops, allowing repetitive positioning.

- TRIPLE-HEAD PRODUCTION PUNCHING LINE

Punch 2 types of hole and cut to length – all in one operation. Consists of a CNC Linear Feeder up to 12 m long (or more if required), with a K210 Controller. A Punching machine with 3 separate punch cylinders and a hydraulic stripper assembly to keep the bar fl at. This versatile unit can handle fl at bar, angle, channel and I-beams.

Interested in finding out more about our Towermak Machine? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.