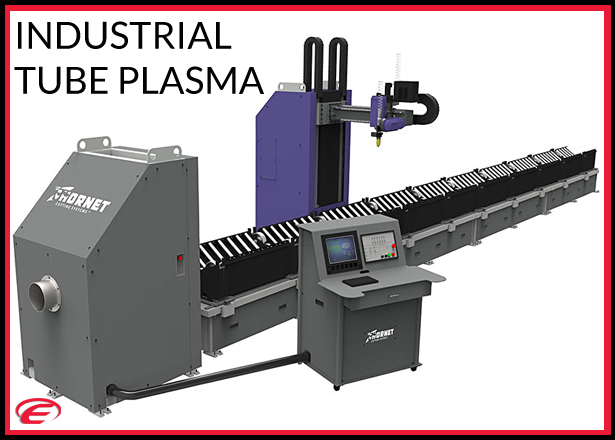

Industrial Tube Plasma

Plasma Pipe Cutting Machine

Roto Hornet 2000 CNC Plasma Pipe Cutting Machine

A combination of our innovative pipe handling system, Rotary Tube Pro software, and Hypertherm’s plasma cutting technology, creates the industry’s best CNC plasma pipe cutting machine. The ROTO HORNET will substantially increase your pipe cutting productivity and boost your bottom line.

Rotary Tube Pro, from Hypertherm, is a comprehensive software solution for designing and cutting tube and pipe parts. Tubes and branches are easily created using parametric input. There is no 3-D CAD experience required. Sidewall cuts can be selected from a list of predefined shapes or added from CAD. If needed, you can also import 3-D CAD files for highly customized pipe cuts. The flexibility provided by Rotary Tube Pro allows fabricators and manufacturers the ability to work efficiently, reducing costs and boosting productivity.

Rotary Tube Pro displays 3-D renderings of the parts being programmed. This allows you to view end types, hole locations, and other features. The 3-D rendering display allows you to visually confirm the accuracy of the part that’s being programmed. Both main and branch pipes are shown to aid in pipe fit-up.

If you require a solution for large pipe cutting either bevel cutting or straight cutting our Roto tube is the solution your business requires . Our systems can be offered all the way up until 12 Metres to accommodate such a large branch.

INDUSTRIAL STRENGTH PIPE CUTTING:

The ROTO HORNET 2000 was designed and developed to increase

production and improve accuracy for your heavy-duty pipe cutting needs.

The innovative pneumatic pipe loading table, Hypertherm’s plasma and

CAM software, and our heavy-duty design are combined to produce one

of the industry’s premier pipe cutting machines.

When it comes to plasma cutting long lengths of heavy wall tube and piping we have the solution you require. The Roto tube system with Hypertherm Plasma is world renowned and industrially recognised..

KEY FEATURES OF THE ROTO HORNET CNC PLASMA PIPE CUTTING MACHINE

- PNEUMATIC PIPE HANDLING

The innovative design maximizes production by quickly and safely handling pipe

- VERSATILITY

Cuts pipe from 2” (50 mm) to 24” (610 mm) in diameter.

- UNIQUE HEADSTOCK DESIGN

Easily align and center pipe for cutting with adjustable 3-jaw chuck

- Pipe turn rolls supported pneumatically

• Hardened urethane wheel material

for maximum durability

• Heavy-wall tubular frame built to last

• Large pipe conveyor rollers

- Program for a variety of cuts, miters,

copes, saddles, hillsides and more

• Optional Contour Bevel Head availability

• Cutting-edge software increases

efficiency and boosts profits

- Quick, efficient, accurate alignment

• Emissions exhausted through

the chuck and headstock

• Maintains a clean, safe and

productive work environment

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Another benefit robotic tube cutting offers is eliminating secondary work by having weld preps done while the material is being processed in one pass. This eliminates jigs, fixtures, clamps, paper templates, angle grinders and sawing equipment, giving our customers a more cost effective solution. Recent developments in high precision/high definition plasma cutting processes has significantly improved the quality and the precise nature of this cutting process and eliminates the need for edge dressing producing a quality product ready for use.

Rotary Tube Pro software enables you to cut a variety of parts including straight, miter, cope, offset cope, slotted straight, and slotted round end pipe cuts. It also allows you to easily cut notch, saddle, offset saddle, and angled saddle branch cuts.

VERSATILITY

Customize your pipe cutting for a wide variety of technical specifications.

• Program for a variety of cuts, miters, copes, saddles, hillsides and more

• Utilize pre-defined or custom shapes and cuts

• Cutting-edge software increases efficiency and boosts profits

UNIQUE HEADSTOCK DESIGN

Easily align and centre pipe for cutting with adjustable 3-jaw chuck

• Quick, efficient, accurate alignment

• Emissions exhausted through the chuck and headstock

• Maintains a clean, safe and productive work environment

PNEUMATIC PIPE HANDLING

The innovative design maximizes production by quickly and safely handling pipe

• Innovative pipe conveyor

• Built-in pipe storage rack

• Rugged tubular frame built to last

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.