Power Bend Pro

CNC PRESS BRAKE

POWER-BEND PRO CNC PRESS BRAKE

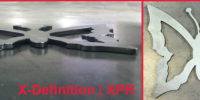

The Power-Bend Pro Series has been re-designed according to the current needs of our users and has reached to a unique structure with its electronic and mechanical equipment which gives excellent results in normal, stainless, thin and thick sheet metals.

The Power-Bend Pro Series Press Brakes are among the most preferred models with the user-friendly CNC control panel and low maintenance requiring hydraulic systems which keep the production costs in your facility at minimum level and reach to high production speeds.

Power-Bend Pro which brings design and technology together will be an economical and permanent solution of your business, in narrow, wide, complex and precise bendings, in mass production requiring single or high speed.

Perfect Combination of Speed & Power

Stronger, faster and deeper bends;

Power-Bend Series machines redesigned based on users preferences to become a unique machine with its individual electronic and mechanical features.

Power Bend Pro 3 Axes CNC Press Brake Series are among the highest rated machines which will help you increase your productivity and keep costs at minimum level with its user friendly CNC controller and low cost hydraulic maintenance.

New Power Bend Pro 3 Axes CNC Press Brake is exactly what you need for your production where complicated, sensitive, single or multiple bends on high speed are paramount.

Some Features to expect with the Power Bend Pro

- EASY SERVICE WITH REMOTE ACCESS

For the solution of defects that may occur in the machine, time loss is minimized by interfering with remote access over the internet (ERTOUCH).

- USER FRIENDLY TOUCH SCREEN

The models can be seen on the screen with the 3D feature of the controller realistically. Thus, it provides the operator with ease of

distinguishing the objects from each other and ease of implementation (ERTOUCH).

- FAST AND EASY TOOL REPLACEMENT

Tools can be replaced without any need for an extra key for the standard used promecams on the machine.

- RIGID UPPER BEAM WITH PRECISE POSITIONED BEARINGS

Thanks to the rigid upper beam operating on bearings at 12 points, with a bending accuracy of 0.01 mm. It is possible to obtain precision bendings.

- FRONT SUPPORT ARMS

Sliding front support arms with stoppers moving with the help of linear rail and bearing.

- EASY MAINTENANCE THANKS TO INDUSTRIAL DESIGN AND FLEXIBLE STRUCTURE

Maintenance and failure intervention times are minimized thanks to easy access to the accessories and the hydraulic systems requiring low maintenance.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.