CNC True Hole SureCut Technology

Maximizing Cutting with Hypertherm SureCut Technology

True-Hole SureCut Plasma Technology

SureCut technology overview:

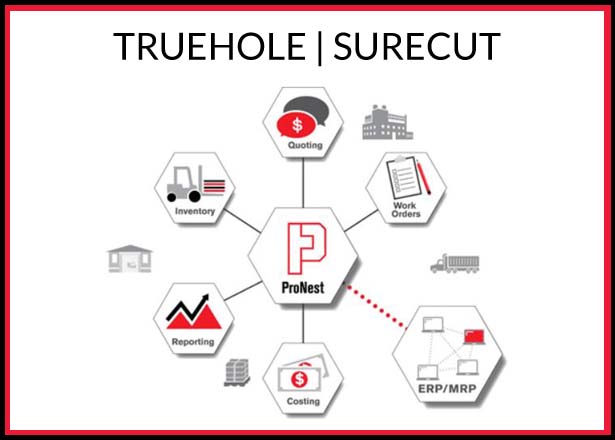

SureCut is designed to maximize cutting performance by automatically applying optimized cutting process parameters to simplify cutting and reduce operator intervention. SureCut is delivered through a combination of Hypertherm products such as automated systems, CNCs and CAM software. Maximizing performance through embedded expertise SureCut technology is brought to you via various delivery mechanisms that include Hypertherm systems, CNCs, and online/offline CAM software.

• SureCut is delivered through a combination of products that include plasma power supplies and waterjet pumps as well as CNCs and CAM software

• Automatically applies optimized cutting process parameters which simplifies cutting and reduces operator intervention

• Easy set up improves job efficiency

• Provides access to Remote Help™ and troubleshooting which reduces downtime

• Works across multiple cutting technologies

Optimum hole quality: SureCut True Hole®:

As part of Hypertherm’s SureCut technology, True Hole for mild steel is exclusively available for use in conjunction with Hypertherm’s HPRXD® and XPR™ plasma systems.

True Hole is automatically applied by nesting software or CNC software to thicknesses up to 25 mm (1inch). Hole coverage ranges from hole diameter to thickness ratios

from 2:1 to as low as 1:1.

Truehole technology requires HyPerformance® Plasma HPRXD or XPR system along with a True Hole enabled cutting machine. Available now from Engineering Machinery & Services

SureCut Technology includes:

- Why SureCut®?

-Bolt hole quality is delivered automatically without operator intervention.

-Narrows the gap with laser hole quality making the plasma process suitable for many jobs previously cut with laser.

-Virtually eliminates hole taper.

-Ding is reduced and biased to the outside of the hole.

-Delivers true “bolt-hole” quality.

- What SureCut™ can do for you:

Hypertherm’s integrated nesting software, CNC, THC, and HyPerformance® plasma cutting systems have more than forty five years of cutting innovation and process knowledge built into them. Our products are designed to work together seamlessly, making it easy to optimize cut quality, parts per hour and cost per part.

-

- The SureCut investment:

Rapid Part technology offers up to 100% increase in productivity, automatically, without operator intervention. Rapid Part technology uses motion optimization techniques programmed into the part program and automatically executed by the Computer Numerical l Control (CNC). Improved productivity: Rapid Part™ Achieve greater productivity by reducing cut-to-cut cycle time. Rapid Part controls and optimizes every step in the plasma cutting process – without operator intervention – so you can focus on your business and your customers.

- SureCut Benefits:

-True Hole technology is a specific combination of the following parameters that is linked to a given amperage, material type, material thickness and hole size:

-Process gas type

-Gas flow

-Amperage

-Piercing methodology

-Lead in/out technique

-Varying speeds across multiple hole segments

-Arc termination synchronized with torch motion

- SureCut benefits:

-Automatically applies optimized cutting process parameters which simplifies cutting and reduces operator intervention

-Easy set up improves job efficiency

-Provides access to Remote Help™ and troubleshooting which reduces downtime

-Works across multiple cutting technologies

-

-

- SureCut Technology includes:

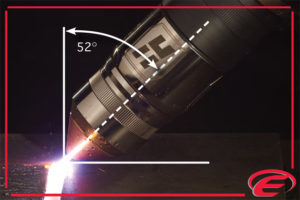

-True Hole®

-True Bevel™

-Rapid Part™

-Consumable Life

-Remote Help™

-Optimize Cut Quality -

Interested in finding out more about our Plasma Machines? - Get In Touch

10 things you didn’t know about plasma cutting:

Today’s plasma cutting technology can transform your cutting operation more than ever. X-Definition Plasma is setting new standards for cut quality on mild steel, stainless steel and aluminum. In fact, cut quality is so good, customers are calling it “laser like”. Want to know what today’s plasma technology is capable of? Watch the video!

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.