Fibermak G-Force Side Loader Laser Cutting Machine

– SL FIBER LASER TECHNOLOGY

CNC Laser G-Force SL Side Loader

Compact Design That Provides 30% Benefit in Terms of Layout…

With its side loading design. Fibermak SL is the best choice for workshops with limited space, without compromising the G-Force standards and quality. If customers have a short hall, they are advised to prefer the side-loaded fiber laser machine. Thanks to the high acceleration in Gen-3 G Force series servo motor models, production time decreases and efficiency increases by 15% per hour.

Thanks to the structure developed on the side-loaded machine. the power panel has been made more compact. Additionally, the equipment used in this machine such as oil reservoir and resonator are placed in the area inside the hood. So, the number of external equipment is also significantly reduced, thus providing great advantages to customers in terms of layout area. As a result, thanks to the side-loaded design, you may benefit from the 30 percent smaller layout area of the machine compared to the standard machine.

SIDE LOADER TECHNICAL SPEC:

CONTROL PANEL

– The unit which controls the system and sends the user commands to the machine

– It is resistant to difficult environmental conditions. (Shock, dirt, humidity, temperature)

– It is used as a touch screen and it is mounted on its functional keyboard.

– You can increase and decrease the axis speeds in the working area.

– Shortcut keys provide ease of use.

– Cutting operation can be monitored instantaneously in NC graphic.

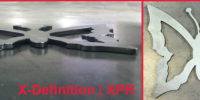

CUTTING HEAD

– The beams produced in the laser unit are carried by the fiber cable up to the cutting head. The head transfers the beams from the fiber cable to the processing surface.

– The laser beam is set at the desired focus with the help of the lenses in the unit.

Key Benefits of the CNC Laser Side Loader

- ROBUST AND STRONG BODY

Thanks to its strong body with its rigidity ensured both in dynamic and static terms. it has a long service life and operates with high precision.

- FLY-CUT FEATURE

With the fly-cut feature of the Fibermak Momentum Gen-3, you can perform cutting at great speeds and great qualities in both circular and parallel lined parts.

- STANDARD EQUIPMENT

4 Axis (X, Y U, Z)

Servo Motor

Automatic focus cutting head

Laser Source

Cooling unit

Clean – dry air system

Safety cabinet

2x Automatic Shuttle table

- FREQUENCY MODULATED CUTTING

Thick material blasting (piercing) is done in a much shorter time and the material to be cut is prevented from getting heated. With the frequency modulation used during cutting and at sharp corners, it also allows thick materials to be cut without erosion in perpendicular corner cuts or without giving radius to the corner.

- PROVIDES TRANSITION AT HIGH SPEED WITH LIFT TRANSITION TYPE

In the transition between the parts, the type of transition that will put the speed and acceleration into practice is as important as the speed and acceleration in question, With the lift transition type used in Fibermak Momentum Gen-3, you will get maximum efficiency from your machine by transition at maximum speed.

- EQUIPMENT CONT.

CAD/CAM Software

15″ Touchscreen Controller

Conveyor

Warning lamp

Nozzle and cleaning kit

Nozzle cleaning and calibration tray

Interested in finding out more about our Side Loader Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.