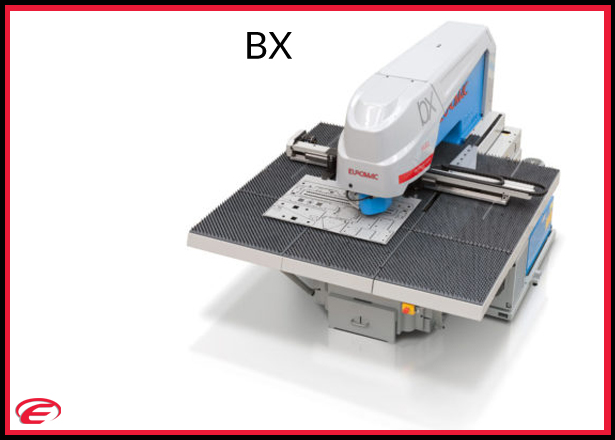

BX Multitool Punch Press Machinery

Punching Machine

BX Multitool Punch Press Machinery

EUROMAC is one of the largest builders of punching equipment in the world. The machines are manufactured in Italy and distributed throughout the Northern Ireland and the Republic of Ireland. Euromac manufacture CNC Punching Machines, Notchers, and Hydraulic Horizontal Benders.

Euromac has put a lot of effort into the development of the console software to allow simple, intuitive, yet productive programming. TopPunch® is the special control program used on the machine. The key TopPunch® features include: – A simple, intuitive user interface that allows parts to be produced in seconds – Total control of the punch list, enabling you to program the stroke, speed, acceleration and dwell time for every single tool. The software also provides also automatic compensation for sheet thickness. Programmable tool grinding alerts are also available. – Graphic turret setup management with automatic checking of consistency between the tools required by the current program and the actual configuration./ – Multitasking: programing, testing and simulation of the next part are all possible while the machine is running – Customization to material: different lubrication rates, axis acceleration and target die clearance can be set for each material. – Batch manager: it is not only possible but actually easy to create a job queue with full programming of the whole output of the day, week or even a longer period.

The Euromac BX Autoindex CNC punching machine has all the benefits of the standard BX Multitool machine, with the added features of 360° bidirectional rotation of Euromacs 4, 6 or 10 station multitools or standard thick turret tools.

With the multitools indexable this creates a powerful production machine at an economic price.

C-frame monoblock:

Our machine frame is a normalized nodular cast iron monoblock in Meehanite® with 65kg/mm2, designed with FEM (Finite Element Method), punching head directly built into the monoblock frame.

In practical terms this means a more robust (no welding points), precise and reliable structure being at the same time compact, hence using less floor space and allowing flexibility in loading different sheet sizes.

A working zone opened from 3 sides makes it easier to load sheet of any format, allows to rotate it and facilitates tooling interchange.

Key features of the Bx Multitool Punch Press Machine

- AUTOINDEX INNOVATIVE SYSTEM

A patent protected solution that increases productivity for a smaller price. A unique direct rotation drive of AutoIndex system uses a smaller number of mechanical parts, increasing reliability and cutting service costs down. The index station may turn whether it contains single tools or MultiTool systems XMTE 4, XMTE 6 and XMTE 10.

- TOP PUNCH TOOLING MANAGEMENT

The CNC router works on Windows with an intuitive user interface in Russian, which makes it easier to understand and shortens the programming time.

- TOOLING

Universal workstations allowing to mount both single tool or multitool for 4, 6 or 10 cutters, make it possible to use workstations for any kind of task and increases the machine flexibility.

- VACUUM SYSTEM

Our Vacuum system Helps to evacuate all the scraps than could remains in the sheet, we recommended the vacuum system in case to punch thin materials from 0,4 to 1mm thickness. (optional)

- COMBINED BRUSHES & BALLS TABLES

Our tables are equipped with Brushes to evitate to mark the sheet during the moving,we can make a combination with balls, recomended in case of sheets over 50 kg.

- PHOTOELECTRIC BARRIER KIT

Kit for modular photoelectric barriers for 1- 2- 3 or 4 sides of machine. Necessary for CE declaration. (optional)

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

Computer numerically controlled (CNC) punching is a sheet metal manufacturing process that is carried out by CNC punch presses. These machines can be either a single head and tool rail (Euromac)design or multi-tool turret design. The CNC punching machine is programmed to move a sheet of metal in an x and y direction so as to accurately position the sheet under the machine’s punching ram ready to punch a hole or form.

CNC turret machines from Euromac can create many shapes, from simple circles or rectangles to overlapping geometrical 3D designs.

CNC punching plays a significant role in sheet metal manufacturing industries in our local markets, delivering machinery with high accuracy, speed that is competitively priced is the reason our Euromac Turret punch systems are the most popular choice for our customers.

Vacuum system Our vacuum system prevents scraps from remaining on the sheet, potentially damaging its surface and sometimes even the tool itself. Strongly recommended when processing thin materials, material with protective film or aluminium in general. Optional on all models.

The processing range for most CNC punch presses is 0.5mm to 6.0mm thick in a range of materials including steel, zintec, galvanised steel , stainless steel and aluminium. The choice of hole punched can be as simple as a circle or rectangle right through to special shapes to suit a specific cut out design. By using a combination of single hits and overlapping geometries, complex sheet metal component shapes can be produced. The machine may also punch 3D forms such as dimples, taptite® screw thread plunges, and electrical knockouts etc on either side of the sheet, which are often employed in sheet metal enclosure design.

By using our Euromac machinery you can have a large number of strokes, with several different tools in turn, a turret press may make a wide variety of parts without having to first make a specialised press tool for that task. This saves both time and money, allowing rapid prototyping or for low volume production to start without tooling delays.

Off-line programming Customer-generated drawings in DXF format (or most common CAD formats) can be speedily converted into Euromac CNC code by many CADCAM packages, readily available to you.

A hydraulic ram forces the tooling into the sheet material held in position by clamps on the bed of the punch. The tooling can then be used to create a number of shapes like:

- Louvres

- Centre punches

- Countersinks

- Embosses

- Knockouts

- Hinge forming

Euromac machines are tailored to meet demanding market requirements; the combination of state-of-the-art technologies and unique concepts assures you advanced, productive and competitive products at all times.