CNC HVR

HYDRAULIC GUILLOTINE SHEAR

The CNC HVR- Variable Rake Hydraulic Guillotine Shear

Excellent cut, perfect speed:

ERMAKSAN, known as one of the top worldwide manufacturers in the sheet metal industry, proudly announces its latest shear model to the market, Variable Rake Hydraulic Guillotine Shear CNC HVR.

Blade gap, cutting angle and cutting length are all adjusted based on material selection and thickness automatically.

By choosing the new and improved CNC HVR, you will bring modern-day technology to your company with maximum safety, high accuracy and unique ease of use.

It can cut all kind of metal sheet to maintain the highest production capacity with maximum precision and quality.

Perfect design in every aspect:

ERMAKSAN improves its reliability every day by working with highly educated engineers and by using the latest technology in rapidly developing sheet metal industry.

By using world standard steel, hydraulic systems and electronic products all your production needs provided.

More than just cutting:

CNC HVR is developed by expert engineers of ERMAKSAN reflects innovative technology with all aspects of it.

Automatic Solutions, Perfect Cuttings…

CNC HVR

HYDRAULIC GUILLOTINE SHEAR

When you enter length, thickness and quality data of the metal sheet to be cut into easily programmable controller; blade gap, cutting angle and cutting length are automatically adjusted at the same moment. This provides flexibility for various production requests, and prevents time losses completely by aiming high efficiency.

By selecting CNC HVR model developed by ERMAKSAN engineers; you will bring up to date technology to your company with maximum safety, high accuracy and unique ease of handling.

Key Features of the CNC HVR Hydraulic Guillotine Shear

- LED FITTED BODY

Aesthetics is added to the machine and additionally machine cutting with light is enabled without any need to workshop lights thanks to LED fitted body.

- CONTROLLER (ErCut7)

7“ touch screen controller developed by ERMAKSAN is very user friendly by its intuitive innterface.

- CENTRAL LUBRICATION

Automatic lubrication ensures the extended lifetime of the machine by lubrication of required parts automatically without operator.‘

- ANTI TWIST SYSTEM

Anti twist system holds the sheet during cutting operation against top blade movement and prevents twisting of thick and narrow cuts.

- RTS (Return To Sender)

RTS system allows to make several operations in minimum time on a same sheet after each cutting operation of the sheet to the front of the machine.

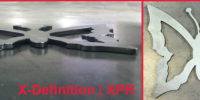

- X TYPE PNEUMATIC SHEET SUPPORT SYSTEM

Pneumatic X type sheet support system ensures more precise cuts with preventing hanging down wide and thin sheets during cutting operation. The main difference of X type levers is to operate parallel to the ground and supporting the sheet all way of cutting.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.