EPL Plasma Truehole Technology

EPL True Hole Plasma Cutting

EPL True hole

Truehole which is part of Hypertherms surecut suite was launched in 2008 with the HPRXD® autogas family of products. It is now also offered on Hypertherm’s XPR™ systems. TrueHole for mild steel produces significantly better hole quality than what has been previously possible using plasma. Equally important, True Hole technology is delivered automatically without operator intervention, to produce unmatched hole quality.

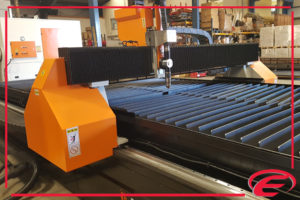

The plasma cutting machine continues to provide wide and flexible solutions with its low investment and operation cost advantages, being appropriate to production lines and automation, improved accurate cutting quality. The EPL series will be profit center of your workshop by its minimum maintenance and consumable part costs and not losing the accuracy for many long years.

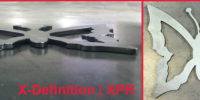

True Hole Technology, which has been developed for carbon steel, comes as standard with XPR 300 and automatic gas consolled of HPRXD plasma system. Patented True Hole technology which was developed for carbon sheet, is a specific combination of cutting parameters which were optimised according to different hole sizes and material thicknesses. With True Hole, you acquire more consistent part dimensions and hence you need fewer second operations. When this technology is compared with other plasma systems in the market, it provides enhancement in quality up to 50% in cylinder holes opened on carbon steel.

EPL True Hole Plasma:

Plasma cutting machinery – EPL Plasma 3 Axes Series; It offers the optimum solution to all your needs with its advanced accurate cutting quality, production line and automation.

Special plasma software and CNC controller enables the operator to use the machine with ease.

R&D engineering calculations; Knowledge gained from research has been integrated into the development of the main frame/body and moving bridge of the EPL Plasma Cutting Machinery giving a higher cutting quality.

EPL Plasma Series is the best and most economical machine when looking at consumable part consumption.

EPL Plasma - High Performance Maximum Productivity

- PRECISE CUTTING QUALITY

While providing high cutting thanks to the X-Definition technology, it also ensures that a precise cutting quality is achieved for a long period thanks to the HyFlow Technology.

- OPTIMUM EFFICIENCY

Essential performance for your business with thicker material drilling up to 20% for stainless steel, and 30% for black sheet, and higher cutting speed up to 15% on thicker materials.

- LOW OPERATING COSTS

Provides more than 50% savings in operating costs while ensuring more than 40% increase in the life cycle of consumables.

- RIGID BODY

It may be used safely for many years thanks to its strong body machined with high precision and guaranteed for both dynamic and static rigidity.

- DO MORE WITH LESS POWER

HyPerformance Plasma enables extremely high cutting speeds per amp with less cutting current than other plasma solutions on the market.

- LONGER CONSUMABLE LIFE

Hypertherm consumables are manufactured with highest quality standards to ensure consistently longer life.

Interested in finding out more about our Plasma Machines? - Get In Touch

10 things you didn’t know about plasma cutting:

Today’s plasma cutting technology can transform your cutting operation more than ever. X-Definition Plasma is setting new standards for cut quality on mild steel, stainless steel and aluminum. In fact, cut quality is so good, customers are calling it “laser like”. Want to know what today’s plasma technology is capable of? Watch the video!

Latest Installation Video :

Engineering Machinery and Services – Ermaksan EPL CNC Plasma The new XPR30 Hypertherm Plasma represents the most significant advance in mechanized plasma cutting technology, ever. This next generation system redefines what plasma can do by expanding its capabilities and opportunities in ways never before possible. With unmatched X-Definition™ cut quaility offered by Engineering Machinery & Services showcases the No.1 plasma on the market

When it comes to CNC plasma cutting, the same basic questions regarding cut quality always seem to surface of industrial cutting processes.

Our Hypertherm Truehole system with Ermaksan cutting table answer all these questions for you!

If you need a production machine for consistent edge and hole quality you need to join the rest of the thousands of happy hypertherm customers and invest in a truehole system.

Bolt hole quality is delivered automatically without operator intervention • Narrows the gap with laser hole quality making the plasma process suitable for many jobs previously cut with laser • Virtually eliminates hole taper • Improves top and bottom level roundness • Delivers true “bolt-hole” quality.

Revolutionary plasma performance: True Hole cut quality As part of Hypertherm’s SureCut technology, True Hole® for mild steel is exclusively available for use in conjunction with Hypertherm’s HPRXD® and XPR™ plasma systems. True Hole is automatically applied by nesting software or CNC software to thicknesses up to 25 mm. Hole coverage ranges from hole diameter to thickness ratios from 2:1 to as low as 1:1. True Hole technology is a specific combination of the following parameters that is linked to a given amperage, material type, material thickness and hole size:

• Process gas type

• Gas flow

• Amperage

• Piercing methodology

• Lead in/lead out technique

• Varying speeds across multiple hole segments

• Arc termination synchronized with torch motion

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.