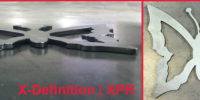

Conventional HD Plasma

SMART PLASMA MAX PRO 200

MaxPro 200 | Conventional HD Smart Plasma

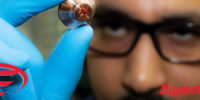

Engineering Machinery and Services Ltd bring to you the Hypertherm – MAXPRO200 plasma cutting system which achieves impressive cut speeds, consistent cut quality and exceptional consumable life with air or oxygen plasma gas. Optimized cutting parameters are automatically set and controlled in one step for easy operation.

Engineered for heavy-duty, high capacity mechanized and handheld cutting and gouging, the MAXPRO200 delivers reliable performance across a wide range of industrial application.

EPL Plasma Smart Series is an economical plasma cutting machine that meet your requirements by using both plasma and oxygen cutting technologies. While saving your budget with Smart Plasma, you may also keep your productivity at the highest level with high quality parts.

MAXPRO200 plasma system

The Smart Plasma is Robust... Precise... Economical...

- LOW COST

Allows high precision cutting using oxygen gas only. Minimizes the cutting costs.

- HIGH PRODUCTIVITY

Brings your productivity to maximum level with its superior cutting quality in your most demanding productions thanks to its cutting speed and fast transitions.

- EASY OPERATION

Optimized cutting parameters are automatically adjusted and controlled in one step to achieve consistent results without operator intervention.

- LOW OPERATING COSTS

Offers the best performance with compromising from its speed using low amperage values. Moreover, it reduces costs per parts and increases the life cycle of consumables greatly using advanced technologies.

- INDUSTRY-LEADING RELIABILITY

Best-in-class manufacturing and extensive testing ensure that every Hypertherm system meets the highest quality standards.

- QUICK TRANSITION

Automatic settings, tool free leads and optional quick disconnect torches let you quickly transition between cutting, gouging, mechanized and handheld processes.

Interested in finding out more about our Plasma Machines? - Get In Touch

Reliable performance Engineered and tested using the same proven design process as the HyPerformance® HPRXD® product family for superior reliability in the most demanding cutting environments.

• During development, Hypertherm systems endure rigorous reliability testing procedures equivalent to years of use in extreme operating environments.

• The MAXPRO200 is built with less than half the number of internal parts compared to other systems on the market. Fewer parts provide greater reliability and serviceability.

• Self-diagnostics are performed automatically at startup and continually throughout the cutting process.

Low operating cost Exceptional consumable life and consistent performance deliver more cost-effective results.

• Do more with less power: patented consumable designs enable best in class cut speeds and robust production piercing using lower amperage levels.

• Superior cut quality and consistency minimize high cost secondary operations.

• Advanced consumable technologies including LongLife®, CoolFlow™ and TrueFlow™ significantly increase consumable life to reduce cost per part.

The fastest most affordable industrial cutting machine in the world which gives you the customer the option to cut with either Air plasma or Oxygen plasma as the cutting gas .

Vertily dross free cutting up to 22mm.

The MAXPRO200 plasma cutting system achieves impressive cut speeds, consistent cut quality and exceptional consumable life with air or oxygen plasma gas. Optimized cutting parameters are automatically set and controlled in one step for easy operation. Engineered for heavy-duty, high capacity mechanized and handheld cutting and gouging, the MAXPRO200 delivers reliable performance across a wide range of industrial applications.

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.